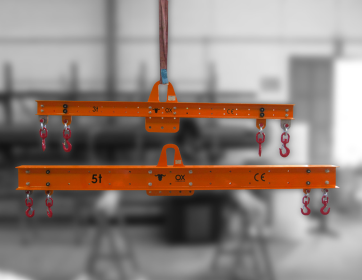

OX lifting beams and beam lifting systems

Suitable for lifting heavy loads using a tailor made lifting system

OX is a versatile solution, with modular lengths able to reach up to 36 meter spans, and with capacities from 6 tons up to 1.350 tons, all of them certified by DNV-GL.

- Available in many adjustable lengths and capacities from 9 to 170 tons.

- All the beams are designed and manufacture to the specifications of current regulations.

- OX lifting beams are smaller and lighter than its competitors, but still contain the same lifting capacity. Therefore, they are more economical in transportation, storage, and installation.

- Easy and fast installation in accordance with the manual.

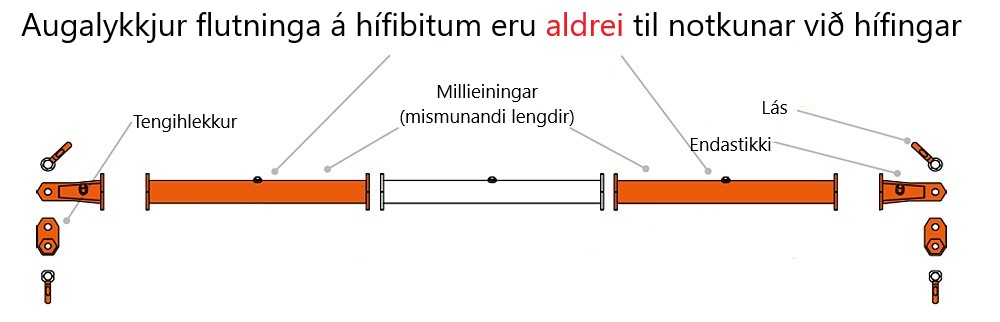

- This is a modular system, making it easy to adjust the system to changing needs only by removing or adding various sections.

- For a lifting of multiple anchor points you can combine spreader beams vertically or form a rectangle with the corners. Especially convenient when lifting shipping containers.

- All systems can be delivered with the correct locks and anchor points. For example, specific wire sling locks that have a large breaking load as well as to protect the wire sling from damage.

OX Worldwide has obtained a DNV-GI certificate for its manufacturing process which speaks to its high quality standards.

- DNV certificate

- DNV GL standard DNVGL-ST-0378. Standards for lifting horizontally and vertically.

- DNV GL standard DNVGL-ST-0377. Standard for lifting ships.

A maximum of 5 sections can be added to each beam for loads up to 170 tons, and 6 sections for loads of 250 tons or more.

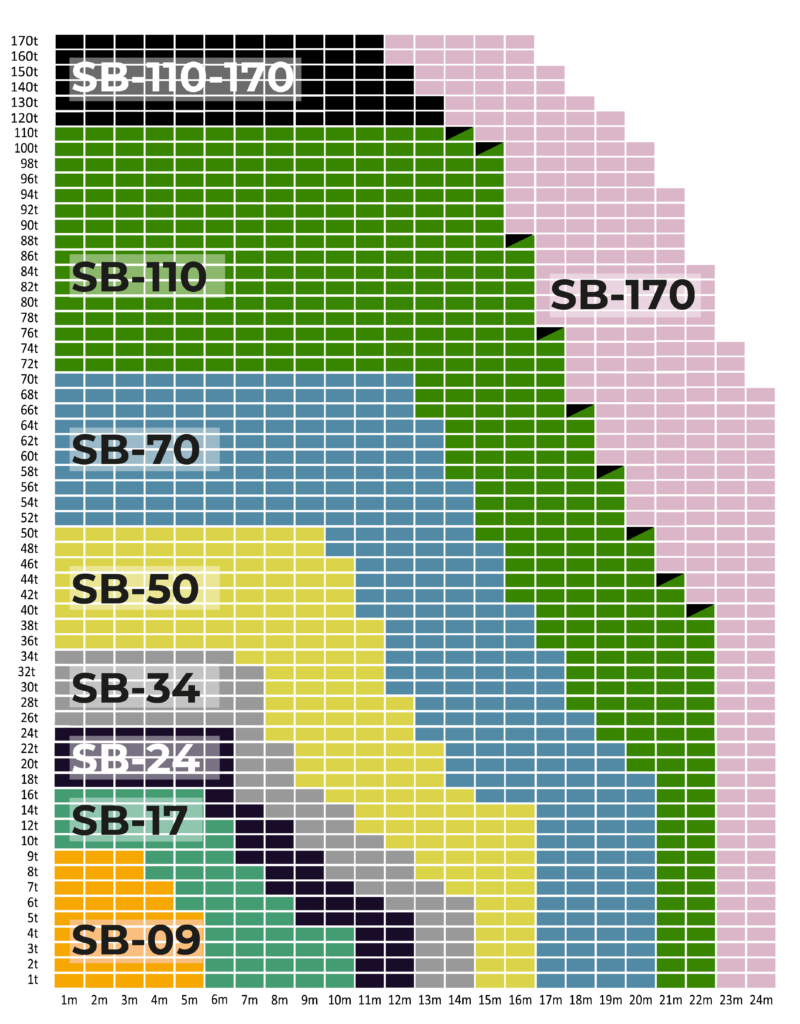

What size lifting beam do I need?

The table below shows the most suitable beam for working load limit for 30° and maximum load of 170 tons. If the load is higher, our experts are ready to help you find the correct beam for the job.

Working load limit (WLL) in tons with 30° loading angle.

OX ECO – Lifting beam

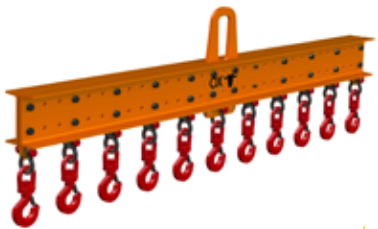

The “Eco-Beam” is an economical and fast-delivery lifting beam. The frame of the Eco-beam consists of one structure with a pattern of holes, a central lifting point and two drop links at the ends. The result is a fixed lifting beam. Once the frame is assembled, a wide range of accessories can be added to the Eco-Beam to solve different needs.

Adjustable

Fixed for upper two leg sling

Multi-point

In addition, OX Worldwide design and manufacture other accessories for the Eco-Beams in order to solve the special needs of each client.