General information

Ísfell prides itself on its versatile and multi-faceted quality products that suit a wide range of applications. Different construction, loading and lashing methods for general lifting applications do not pose a particular challenge for our universally applicable lifting accessories as they were manufactured with precisely these different demands in mind.

All information on design and load capacities in the catalogues (Uniform Load Method) take this range into account. There is also an alternative method in existence for rating the product load capacity, for which the specific application scenario of the chain and all operating conditions must be known. In such a case, please contact the Ísfell Technical Service team, as the information contained in the catalogue does not apply to such processes.

Responsibility is key

If the Ísfell lifting accessories are used correctly and by competent persons, they have a long lifespan and provide the highest possible safety standards. Material and personal damage can be avoided by reading this user information carefully and handling all lifting processes in a responsible, provident manner.

Changes to the condition as delivered

We urgently recommend using only the original parts that are included in the scope of delivery with lifting chains from Ísfell (bolts, safety pins, screws etc.) Modifying the original condition of the lifting accessories by bending, grinding, removal of parts, welding, drilling, stamping etc. means exposing yourself and others to unnecessary danger In such a case, safety can no longer be guaranteed and usage becomes dangerous.

Risk factors and conditions include heating the chains to a temperature of more than 380 °C (pewag winner 400) and removing safety parts such as safety pins, safety catches etc. Do not apply any surface coatings to chain slings, i.e. do not subject them to hot galvanizing or electrogalvanizing.

If any surface treatments are required, please make sure to double-check with the service team

at Ísfell or the manufacturer first. Dipping or removing a coating with chemicals are potentially dangerous processes that may give rise to hazards. We urgently recommend customers to check with the Ísfell technical team first.

Restrictions of use

For hazardous or dangerous conditions, please contact the Ísfell technical team.

Temperature effects

Lifting and lashing systems and accessories have a defined temperature for optimal usage, which is between -40°C and 200°C. The lifting accessories must on no account be used outside the indicated temperature range. If this has been the case, the chains must be removed from service and/or the lifting accessories have reached room temperature.

Effects of acids, caustics and chemicals

Lifting accessories must not be used in acids or caustic solutions or be exposed to their vapours. Please be aware of this requirement at all times as certain production processes release acids and/or vapours! If the use of lifting accessories with highly concentrated chemicals in combination with high temperatures cannot be avoided, please make sure to obtain the express approval of such usage by our experts.

Hazardous conditions

The working load limits in this catalogue have been determined on the basis that the product is not being used in hazardous conditions. Hazardous conditions are present when lifting accessories are used offshore or for the lifting of persons or potentially dangerous goods such as liquid metal, corrosive or caustic substances or nuclear material. If the chain sling is to be used for such purposes, the extent of the risk is to be assessed by an expert, the load capacity must be adjusted accordingly and incorrect usage in hazardous conditions must be avoided at all cost. As a rule, usage in hazardous conditions should be avoided.

Prevention is better than cure!

Before using any lifting accessory, several inspections must be performed:

• Does the lifting chain correspond to the order?

• Has the inspection certificate or certificate of conformity been supplied?

• Do the markings and load capacities stated on the chain sling correspond to the information given on the inspection certificate or certificate of conformity?

• Have all the particularities of the chain sling been entered into a register of lifting equipment, if required?

Please check the lifting accessories for visible signs of damage or wear prior to each use. In case of any doubt or damage, do not use the chain slings and have them inspected by a competent person.

Inspections by a competent person must be performed in accordance with national legislation, but at least once every 12 months. If the chain sling is frequently used at its full load capacity, more frequent inspections are required!

Ísfell recommends that all lifting equipment be thoroughly inspected at least once a year!

Visual inspection criteria

If at least once of the criteria listed below manifests itself during the visual inspection, all parts must be removed from service:

• Breakage of a component.

• Illegible or missing marking of the chain sling (i.e. information on identification data and/or load capacity).

• Deformation of suspension or sling parts or the chain itself.

• Elongation of the chain resulting in t > 1.05 tn. (see diagram here below)

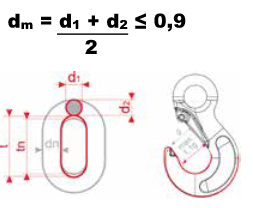

• Wear as determined by the mean value of two measurements of diameters d1 and d2 carried out at a right angle as shown. The chain must be removed from service life if:

• Visible damage such as cuts, notches, grooves, surface cracks, discolouration due to excessive heat exposure, signs of subsequent welding, bent or twisted links or other flaws.

• Obvious wear or chemical removal of material if the admissible dimensional changes as outlined in the table supplied has been exceeded, e.g. pitting corrosion.

• Cracks and cross-cracks that are visible to the naked eye.

• Missing or non-functional safety device as well as signs of widening or twisting of hooks, i.e. noticeable enlargement of the opening or other forms of deformation. The critical point is reached when the enlargement of the opening exceeds 10 % of the nominal value or if the safety catch is open, as this indicates that the hook is overloaded.

Correct maintenance

Please note that all maintenance activities of lifting accessories must be handled by competent persons to minimise the risk of improper use.

Precise documentation

All inspections and their results must be recorded and these records be kept throughout the service life of the chain slings. Precise records of this sort constitute the best basis for effective maintenance.

Storage

Lifting chains must always be stored in a clean and dried condition and protected against corrosion, i.e. slightly lubricated.

Maximal approved dimensional change

Correct use of chain slings

The right angle of inclination

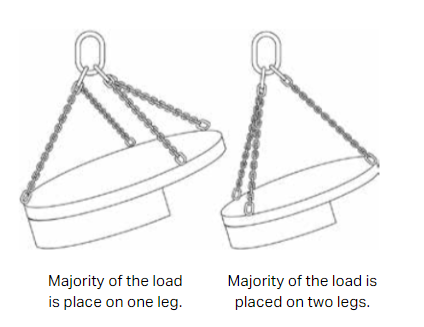

To ensure safe handling, the slinging points and chain sling types must be selected in such a way that the angles of inclination of all chain strands (legs) lie within the data given on the load capacity tag. Preferably, all angles of inclination should be the same. Avoid angles of inclination of less than 15° because of the high risk of load instability Never use chain slings with the angle of inclination exceeding 60°!

Edge-loading – know your limits

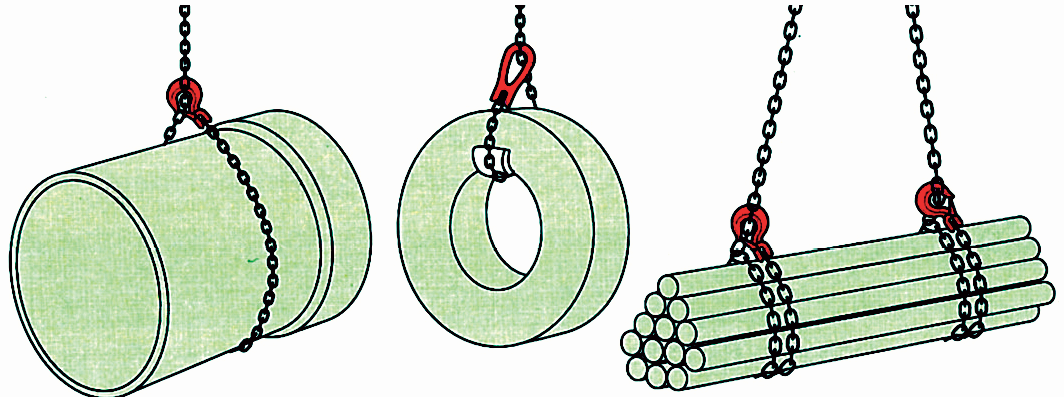

The maximum load capacity of pewag chain slings assumes that the individual chain legs are pulled straight under load, i.e. that they do not run over edges. However, if edge-loading is unavoidable, load protection (packing) should be used to avoid damage (see illustration):

If chains are guided over edges without proper protection, their load capacity is significantly reduced and safe usage can no longer be guaranteed. See the table on page 20 for the corresponding load factors. Where chain have to be looped around beams or other round-shaped loads, the diameter should be at least twice or 3 times the chain pitch. For smaller diameters, the load capacity of the chains must be reduced by 50%.

Impact-/shock-loading

For the load capacities of pewag lifting chains to apply, it is assumed that the individual chain strands are not subjected to impact- or shock-loading.

Classifications of impacts

• Slight impact may result from accelerated lifting or lowering operations.

• Medium impact may result from the chain slipping while adjusting itself to the shape of the load.

• Strong impact results for instance from the load falling into the unloaded chain.

Vibrations

If they are used correctly, pewag lifting chains and accessories withstand high load cycles, with a standard rating of 20,000 load cycles. In case of high dynamic loads, there is a risk of the chain or components getting damaged. If the lifting accessories are in continuous usage everyday it is recommended reducing stress at WLL by using a larger nominal thickness/size in such a case.

Symmetrical loading

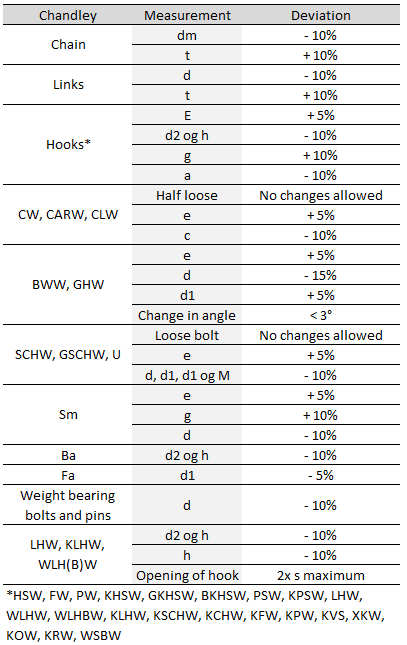

For the load capacities of lifting chains to apply, it is assumed that the individual chain strands are placed under load symmetrically. When the load is lifted, this results in equal angles of inclination and the individual strands are symmetrical to each other.

The load may be considered symmetrical when all of the following conditions apply:

• The load is less than 80% of the indicated load capacity

• The angles of inclination of all chain strands are not lower than 15° and are very similar (i.e. only differ by a maximum of 15°).

• For three- and four-stranded lifting chains, it must be ensured that the corresponding plan angles are within 15° of each other.

Be careful!

If not all of these parameters are complied with, the load cannot be considered symmetrical and the classification of the lifting operation must be left to an expert. In case of doubt, only one chain strand (leg) should be considered as load-bearing. For the corresponding load capacity values, please refer to Keðjutafla Ísfells to determine the precise load capacity.

Wrongful use of defeats the purpose

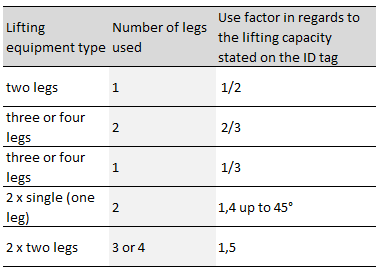

Quality lifting chains offer perfect quality standards if they are used according to their intended purpose. In cases where not all individual legs are used simultaneously or where several lifting chains are used at the same time, different load capacities apply as outlined in Keðjutafla Ísfells. In case of doubt regarding the intended purpose, the load capacity as indicated on the tag must be amended in accordance with the following table:

Precautions

• Hang any individual strands (leg) that you do not use back into the master link to prevent hazards caused by freely swinging chains or unintended hooking.

• Before using several chain slings at the same time, make sure that the crane hook is big enough for all the master rings. Make sure that the master rings cannot fall out of the hook during lifting.

• Angles of inclination of more than 45° must be avoided

• Use only chain slings of the same nominal thickness and grade at the same time.

Additional detailed information

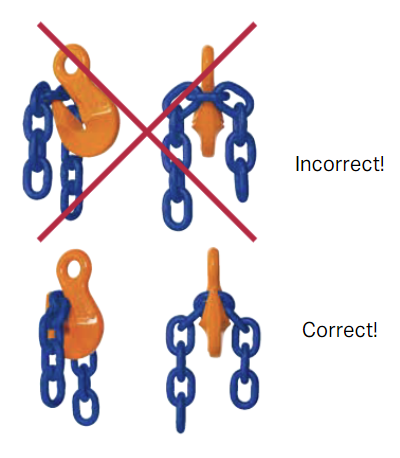

Never tip-load the hook!

Some good advice

Lifting

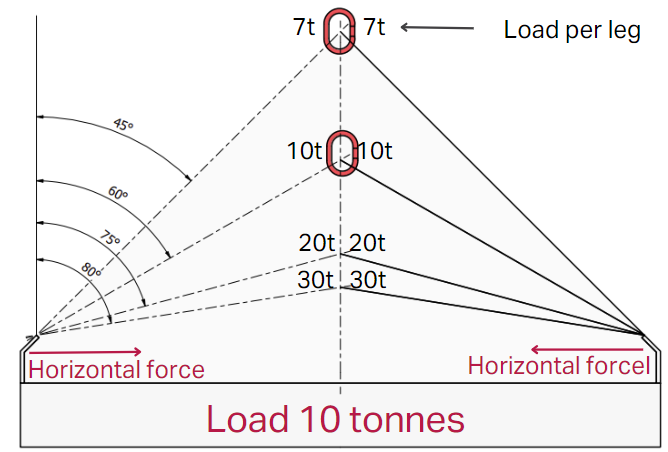

When lifting, it is adamant that it is understood how angles affect lifting equipment.

The diagram here below shows how the strain on a two sling chain lifting 10 tonnes multiplies

as the load angle increases.

A large load angle is cautionary

Warning!!!

• Make sure that the load never exceeds the WLL that is printed on the load capacity tag.

• Ensure that angle β is never larger than 60° from a horizontal line.

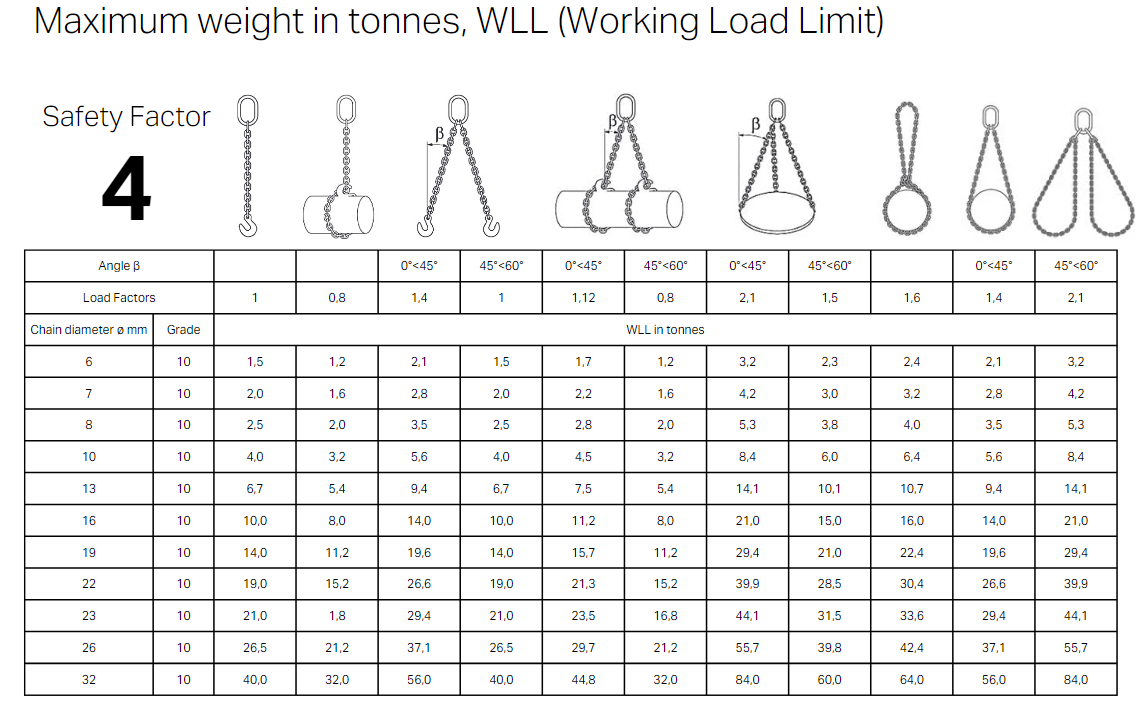

Standards

All lifting equipment from Ísfell is manufactured to the standard of EN 818 and EN 1677, lifting chains according to EN 818-2 and accessories according to EN 1677. Ísfell’s Chain Load Capacity Table is in compliance with WLL according to EN 818-4 with safety factor of 4:1.

Choke hitch

Be cautious when lifting using a nose pull. WLL decreases by 20% when using a nose pull.

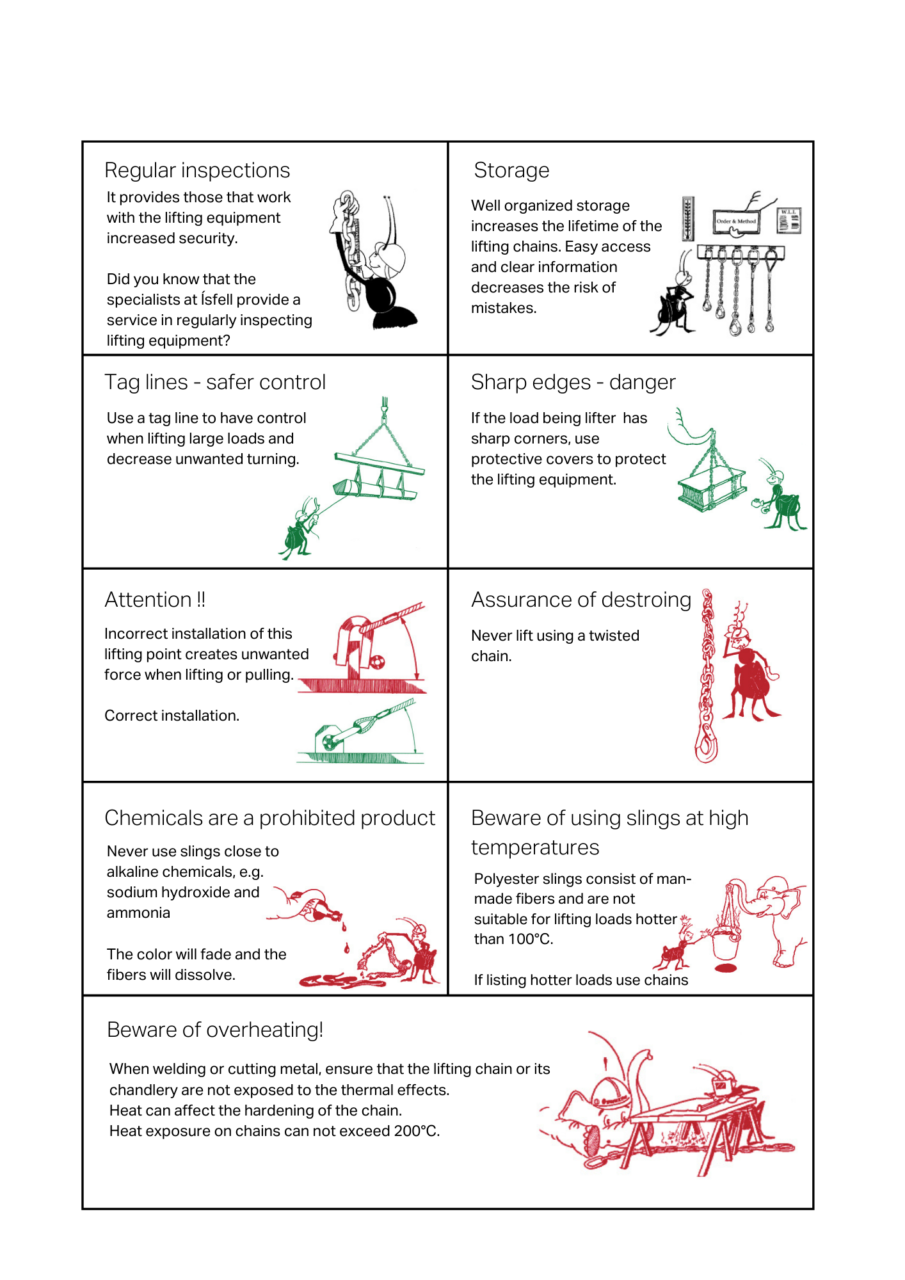

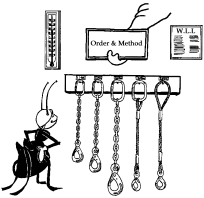

Storage

Well organized storage increases the lifetime of the lifting chains. Easy access and clear information decreases the risk of mistakes.

Regular inspections

Regular inspections provides the users of the equipment increased assurance of its safety. Our experts are Ísfell provide a comprehensive inspection service on lifting equipment.

If the lifting equipment is used under difficult conditions such as high temperatures, imbalanced load, on sharp corners, or when there is a possibility of a sudden shock loads, it is not permitted to use the equipment at full load limit. Specialized equipment is available for lifting at less than 45° and therefore increase the WLL of the lifting equipment.

Ísfell ehf is a member of the Lifting Equipment Engineers Association. LEEA is established across the world as the leading trade association for all those involved in the lifting industry. They are leading in accrediting companies that use and manufacture lifting equipment.

Lifting shipping containers

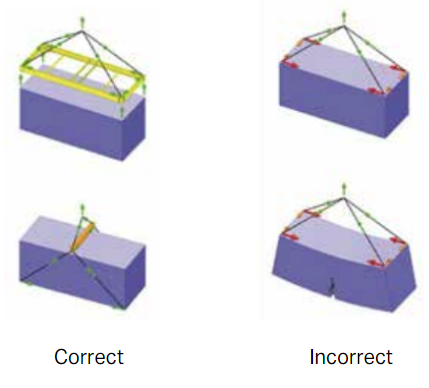

How to lift a container

Thousands of shipping containers are lifted all over the world daily, but lifting shipping containers does not come with its own risks. For various reasons (limited hight, limited lifting capability of the crane, a.s.f.), it is asked if it is really necessary to use a lifting frame when lifting shipping containers. In most cases, the answer is YES.

Why is it not advised to lift a shipping container using only a four sling lifting equipment attached to the top corners

Using a four strand lifting system attached to the four top corners to lift a shipping container creates stress on the roof and sides of the container. Shipping containers are not designed to take increased stressed on the roof and side panels. The strength of the roof panel can vary between containers, all depending on the manufacturer, age, size etc. Therefore, it is possible that a shipping container that is only lifted using a four strand lifting system doesn’t show any signs of excessive stress or any other potential problems. This could lead to continued use of improper lifting practices which could eventually lead to the shipping container breaking.

Why use a lifting frame

When using a lifting frame the tension is disbursed evenly on the frame of the shipping container (see diagram below) instead of the roof panel. The frame of the roof panel is therefore free of the strain that would otherwise have occurred. Today shipping containers are lifted horizontally, which is in accordance with ISO 1496.

Using a (semi-automatic) lifting frame also increases the speed of which the shipping containers can be handled and it saves manpower.

What should be done if there is no lifting frame available

It is possible to lift shipping containers without the use of a lifting frame. In those instances it is recommended to use container hooks that attach to the bottom frame of the container. This distributes the stress of lifting onto the bottom frame which is much stronger than the top frame. This method is in accordance with ISO 1496.

This lifting method also decreases the lifting hight.

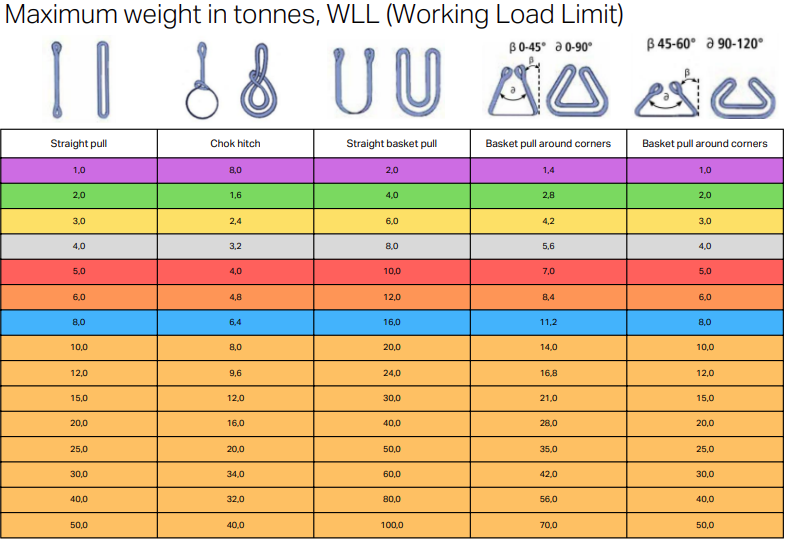

Sling table

Safety rules for when using polyester slings

- Never exceed the WLL of the sling.

- Never used a damaged sling.

- Never connect an eye without an eyelet to something that can damage the sling. What is connected to the eye should be:

- smooth and without sharp edges.

- with a large enough radius.

- not so big that is stretches out the eye.

- What is connected to the eye should be:

- smooth and without sharp edges.

- with a large enough radius.

- not so big that is stretches out the eye.

- Practice extreme cautions and use a sling that has ample bearing capacity:

- when the exact weight of the load is not known.

- when shock-loading is a possibility.

- during exceptionally difficult circumstances.

- when life or limbs are at risk.

- Always take precaustions to protect the sleeve when there is risk of friction or cutting.

- Take the following precautionary measures to increase the lifetime of the sling:

- never, under any circumstances, tie knots or twist the sling – this could result in loss of strength and sling damage.

- a sling should never be pulled from an elevation.

- never leave a load for long periods of time on a sling.

- never drag the ling underneath a load.

- avoid impact- and/or shock-loading.

Polyester slings and heat and chemicals

ATTENTION washing the sling using cold water and cleaning chemicals is necessary to prevent damage.

Polyester

Acids

Some polyester slings can handle acid at room temperature, but we recommend that users contact our experts before working with acids.

Alkalis

It is nor recommended to use polyester slings when working with strong alkalis.

Heat

The material tolerates dry heat well. Normal strands can withhold 80% of its bearing capacity after 30 days of continuous exposure to 150°C. For example, polyester slings were used to hold a load at 150°C for 30 minutes at a time, four times a day without decreasing its bearing capacity.

Never tie knots in the sling – this will result in loss of strength and sling damage.

Make sure that the sling never comes in contact with alkalis chemicals such as amoniak.

Damaged slings that do not meet safety standards should be disposed off.

Supervision when using polyester slings

Examples of defects and damages that are likely going to impact the safety of a sling:

- External damages are an indication of possible internal damage. Vertical or horizontal cuts, as well as all other damages in the weave, on the outer cover of the sling are a strong indication of damage to the core of the sling. DISCONTINUE USE.

- Isolated damages caused by friction can affect the bearing capacity significantly. DISCONTINUE USE.

- It is normal that some markings and minor friction damage appear during normal usage. However, if isolated damage caused by friction has reached the core of the sling DISCONTINUE USE.

- Knots on a sling can reduce its bearing capacity by 25% – 100%. Never, under any circumstance, tie knots in the sling. If a knot appears DISCONTINUE USE.

- Vertical or horizontal cuts to the outer cover of the sling as well as damage to the core of the sling DISCONTINUE USE.

- Vertical and/or horizontal cuts or friction damage to the edges. DISCONTINUE USE.

- The usage of harmful chemicals can weaken and/or soften the sling material. This can be seen of the sling cover starts to peel and it is possible to peel and/or massage it off. Any chemical damage to the cover strongly indicates that the core of the sling is no longer safe. DISCONTINUE USE.

- Vertical and/or horizontal cuts to the cover or core of the sling. DISCONTINUE USE.

- Vertical and/or horizontal cuts or friction damage to the edges. DISCONTINUE USE.

- Unmarked slings should never be used. All tags and markings need to be legible. DISCONTINUE USE.

- Hooks and other fittings that are too big can damage the sling. DISCONTINUE USE and/or get advice from our experts.

- Heat and friction damage results in a shiner cover. In the most serious cases the fibers have melted together, this indicates that the bearing fibers are weaker or they have worn out. DISCONTINUE USE.

Interplay between angles and angle factors

Example of calculations of the effects of an angle on the angle factor

For example, if we have a block that has a Working Load Limit

(WLL) 4 t, the load the block can take is a follows: 0° = 4/2 = 2

t. In other words. WLL 4 t divided by the angle factor 2 (the angle of 0° has an angle factor of 2). Therefore, if we apply maximum WWL, then the minimum angle is 120°.

| Working angle | WWL / Angle factor | WLL t |

| 45° | 4/1,84 | 2,17 t |

| 90° | 4/1,41 | 2,84 t |

| 120° | 4/1 | 4,00 t |

| 135° | 4/0,76 | 5,26 t |

Choosing a block

- In order for the block to be suitable for lifting, the following markings need to be present: CE conformity code, WLL, manufacturer’s symbol, and the serial number.

- The size of the sheave corresponds to the diameter of the wire. If the wire is too big or too small, this can effect the performance of the block and wear out both the wire and the sheave quicker.

- What is the most used angle between the lead and the load line. See table 1 for more information.

- In many cases the crane wire is a limiting factor when measuring how much can be lifter. For example, a standard 19x7mm crane wire with a steel core has a WLL of 1,06 t and in more cases the wire has an aluminum or steel ferrules pressed on to create an eye. When ferrules are pressed onto a wire the WLL of the wire decrease by 20%. Therefore, in this instance, the WLL of the wire would decrease to 848 kg.

Loads on blocks

The WLLs of our blocks are the maximum loads to be applied to the blocks and

their connecting fittings.

The load on a sheave or block varies with the angle between the lead and load line – see figure 1.

When the two lines are parallel, 1 t on the lead line results in a load of 2 t on the fitting. As

the working angle between the lines increases, the load on the fitting is reduced by the angle factor

as per table 1. All loads shown ignore frictional losses in

the lifting system.

| Working angle | Angle factor |

| 0° | 2,00 |

| 10° | 1,99 |

| 20° | 1,97 |

| 30° | 1,93 |

| 40° | 1,87 |

| 45° | 1,84 |

| 50° | 1,81 |

| 60° | 1,79 |

| 70° | 1,64 |

| 80° | 1,53 |

| 90° | 1,41 |

| 100° | 1,29 |

| 110° | 1,15 |

| 120° | 1,00 |

| 130° | 0,84 |

| 135° | 0,76 |

| 140° | 0,68 |

| 150° | 0,52 |

| 160° | 0,35 |

| 170° | 0,17 |

| 180° | 0,00 |

Figure 1

Table 1

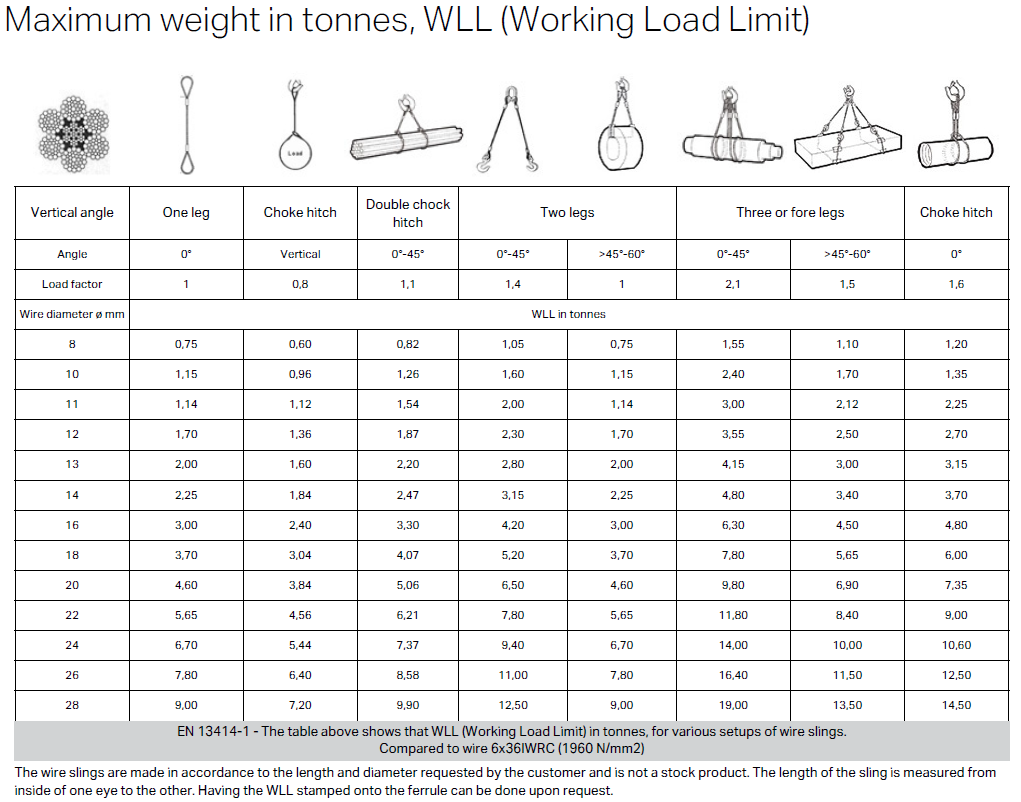

Wire slings

Instructions for a safe use of wire slings:

- It is adamant that a visual inspection of wire slings and wire sling systems takes place before every use. The inspections should take note of any surface damage, check if there are any breaks in the wire, check if there are any visible corrosion or tears.

- If there is any doubt, seek advice from an expert.

- Before every use, make sure that the wire sling is appropriate for the intended use.

- When it is intended to lift a load using multiple wire slings or a wire sling system, it is critical that the load is distributed equally across all the wires.

- An inspection of the fittings that have been pressed onto the wire needs to take place (ex. ensure that no ends are sticking out).

- Ensure that the eye of the sling is the correct size in relation to the hook which is intended to be used.

- It is necessary to use H or D locks or other certified fixtures when connecting/fixing the eye of the wire sling to the hook of the crane.

- Ensure that the hook on the crane has the necessary equipment/fixtures that prevents the wire sling or wire sling system from slipping of the hook.

Wire sling table Ísfells

Open wedge sockets

The wedge and body act as a vice which grips the wire rope and locks it in place. Green Pin® wedge sockets may be used within the range of wire rope diameters as shown in the table here.

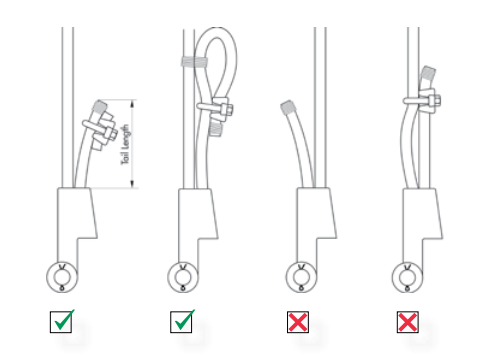

Before use always inspect the socket, the wedge and the pin. Use only with standard 6-8 strand wire rope Always be sure that socket and wedge have the correct size for the wire rope diameter. The loaded part of the steel wire rope should be mounted in the centre line of the pin. When installing the wire rope, always pre-load the wedge with the wire rope in place and ensure that the wore rope sits correctly in the socket. The use of a hammer can be used to seat the wedge and rope into the socket as deep as possible. Never weld the tail.

Check the assembly regularly; re-tighten or re-position if necessary. Never side load a wedge socket as it has not been designed for that purpose. Load may slip if the connection is not properly installed. The efficiency of a wire rope – wedge socket connection is 80% of the minimum breaking load of the wire, but is limited to the minimum breaking load of the socket. Only use the original wedge supplied by the manufacturer of the socket and be sure it is suitable for the diameter of the rope used. Never use a wedge from any other supplier than the original socket supplier as the dimensions will not match.